The Importance of Microelectronics in Drilling Applications

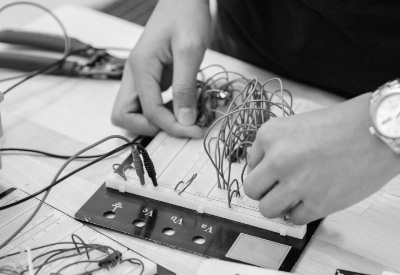

Microelectronics are a crucial component driving modern drilling processes, providing precision, control, and real-time monitoring essential for the challenges associated with drilling industry needs.

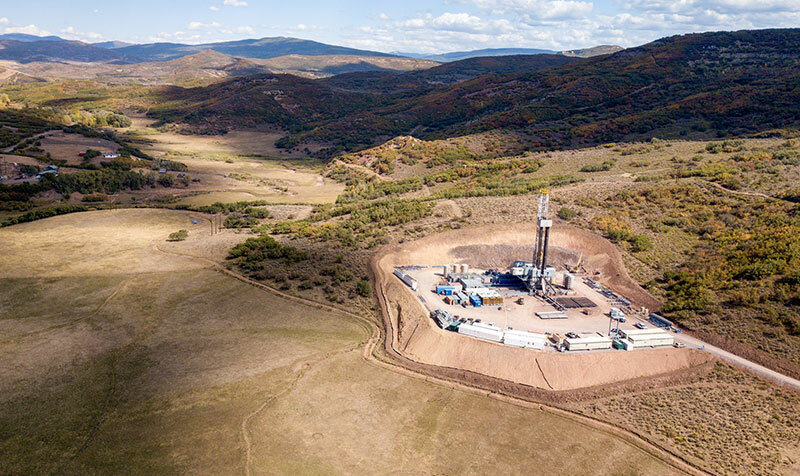

Drilling operations occur in nearly every environment, often exposing machinery to intense temperatures, vibrations, and other physical and environmental stressors that put immense strain on electronic components, including associated microelectronics. City Labs’ NanoTritium™ batteries offer a durable and long-term solution as a power source for low-power microelectronics associated with drilling applications, especially those in harsh and remote environments.

As the drilling industry continues to evolve, the integration of innovative technologies and reliable power sources will play a critical role in the future of drilling. City Labs is dedicated to continuously developing our batteries to provide new low-power energy possibilities and is already partnering with global experts across the world.

Overview of Microelectronics in Drilling

Microelectronics play an essential role in the field of drilling, seamlessly integrating advanced sensors for efficient data collection. Embedded in various electronic components associated with drilling operations, these sensors gather vital information about subsurface conditions and enable real-time analyses for informed decision-making.

In addition to sensor technology, microelectronic control systems are instrumental in ensuring the precision of drilling equipment. These control systems contribute to enhanced accuracy, minimizing the risk of errors and ultimately improving operational efficiency. Real-time monitoring and diagnostics are imperative in preventing malfunctions and ensuring the longevity of drilling equipment. Microelectronics allow for continuous health monitoring of components, enabling proactive maintenance measures.

Furthermore, automation driven by microelectronics brings optimization to drilling processes. This automation facilitates various drilling tasks, reducing the need for manual intervention and significantly improving overall efficiency in drilling operations.

Benefits of Microelectronics in Drilling

The integration of microelectronics in drilling offers numerous benefits that collectively enhance the overall efficiency and effectiveness of the process.

Microelectronics are crucial to high precision and efficiency, ensuring expedited drilling times and higher success rates in reaching targeted reservoirs. Sensors and other microelectronics are used to conduct real-time monitoring and diagnostics, actively identifying potential drilling issues before they escalate to dangerous, costly, and potentially catastrophic scenarios. This proactive approach not only reduces unplanned downtime but also minimizes maintenance costs, thereby extending the lifespan of drilling equipment and reducing other risks, such as environmental contamination.

The incorporation of microelectronics also contributes to a substantial improvement in safety and risk management for drilling efforts. Through better control and continuous monitoring, automated systems and real-time data analysis work together to decrease the likelihood of accidents, fostering a safer working environment for all involved.

Ultimately, the integration of microelectronics in drilling makes overall operations safer and more cost-effective by providing real-time data that allows drill operators to make informed and prompt decisions.

Notable Applications of Microelectronics in Drilling

Directional Drilling

Microelectronics enable sophisticated directional drilling techniques, allowing precise navigation through subsurface formations. This technology enhances downhole drilling accuracy, minimizes environmental impact, and increases the success rate of hole drilling operations.

Mud Logging

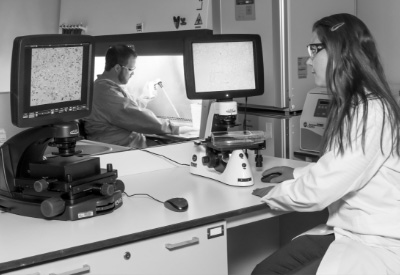

Incorporating microelectronics in mud logging enhances the collection and analysis of drilling mud data. This data is crucial for evaluating subsurface conditions, identifying potential hydrocarbon reservoirs, and optimizing drilling parameters.

Wellbore Imaging

Microelectronics contribute to advanced wellbore imaging technologies, providing detailed images of the subsurface. This information aids in better understanding geological formations, improving reservoir characterization, and guiding drilling strategies.

Real-Time Data Analysis

The ability to analyze drilling data in real-time using microelectronic-powered sensors facilitates quick decision-making by processing vast amounts of data instantly, allowing drill operators to respond promptly to changing conditions.

Drill String Vibration Monitoring

Drill string vibrations that occur when drilling holes can impact drilling efficiency and equipment lifespan. Microelectronics-based vibration monitoring systems can detect and mitigate these vibrations, ensuring smooth drilling operations.

Pressure and Temperature Monitoring

Microelectronic sensors accurately monitor pressure and temperature downhole. This data is critical for ensuring wellbore integrity and optimizing drilling parameters to match subsurface conditions.

Drilling Automation

Automation powered by microelectronics enhances drilling efficiency by automating repetitive tasks, reducing human error, and enabling continuous and high-precision operations even in challenging environments.

Challenges and Future Trends

As drilling efforts continue to explore new territories, the industry faces the notable challenge of developing equipment with durable and reliable microelectronic components that can survive environments that may be otherwise deemed too harsh for current drilling technologies. Additionally, the increasing connectivity in drilling operations raises concerns regarding data security and privacy. To address these concerns, future trends are expected to witness the implementation of secure communication protocols and encryption, providing additional layers of protection for sensitive drilling data.

Another opportunity for growth in this field is developing more seamless integrations between microelectronics and other drilling-relevant technologies, such as advanced imaging and robotics. This initiative is a strategic focus for the future, aiming to establish a comprehensive and interconnected drilling ecosystem that maximizes efficiency.

Lastly, the incorporation of artificial intelligence (AI) and machine learning (ML) in drilling efforts holds great potential to further maximize drilling operations. These technologies bring forth the potential to rapidly and autonomously optimize drilling parameters, predict equipment failures, and continually enhance drilling efficiency in real time. As the drilling industry advances, the interplay between microelectronics and AI/ML will likely become more intertwined and play a key role in shaping the future landscape of drilling operations.

How City Labs’ NanoTritium™ Batteries Can Be Used in Drilling Applications

City Labs’ NanoTritium™ batteries offer a sustainable and reliable power source for microelectronics in drilling applications. Utilizing the natural radioactive decay of tritium, our nuclear battery technology provides continuous electrical power independent of temperature and environmental conditions.

As such, our NanoTritium™ battery products stand ready to revolutionize drilling applications that rely on microelectronics—where reliability, durability, and longevity are paramount. Their 20+ year lifespan, resistance to extreme temperatures and vibrations, and predictable power output make them especially ideal for powering microelectronics in remote and challenging drilling environments.

If you are intrigued by the possibilities of NanoTritium™ batteries for microelectronic drilling applications, contact us today to explore how these cutting-edge power sources can redefine your drilling operations.

The Nuclear Battery Company with a Vision

Reach out to us to discuss your platform’s power needs and how City Labs’ power solutions can help it run longer and more efficiently.

Contact Us Today