Microelectronic sensors have become a crucial component across the industrial market. These devices serve as the eyes and ears of industrial processes, enabling real-time monitoring, data collection, and automation.

However, these sensors remain ill-suited for challenging environments, and they are often unable to provide reliable, long-term power in many industrial settings. As such, there is a great need for novel power solutions to address these limitations.

Microelectronic sensors are designed to capture and transmit crucial data points in real time. The information provided by these sensors is crucial for key decision-making processes and can be used to implement predictive maintenance strategies, identify areas for optimization, and enhance overall logistics and operational efficiency.

What Are Industrial Markets?

Industrial markets include various sectors, including manufacturing, energy production, transportation, and infrastructure development. Industrial processes within these sectors involve complex machinery, infrastructure, and detailed operations that necessitate precise monitoring and control.

These markets share a common need for efficiency, safety, and productivity. Whether it’s the manufacturing of goods, the generation of energy, or the transportation of materials, real-time data provided by microelectronic sensors are vital for optimizing processes and ensuring seamless operations and safety. As such, improvements in microelectronic sensor technology that can enable new operational capabilities is an area of great interest for industrial markets across the board.

Challenges in Industrial Markets

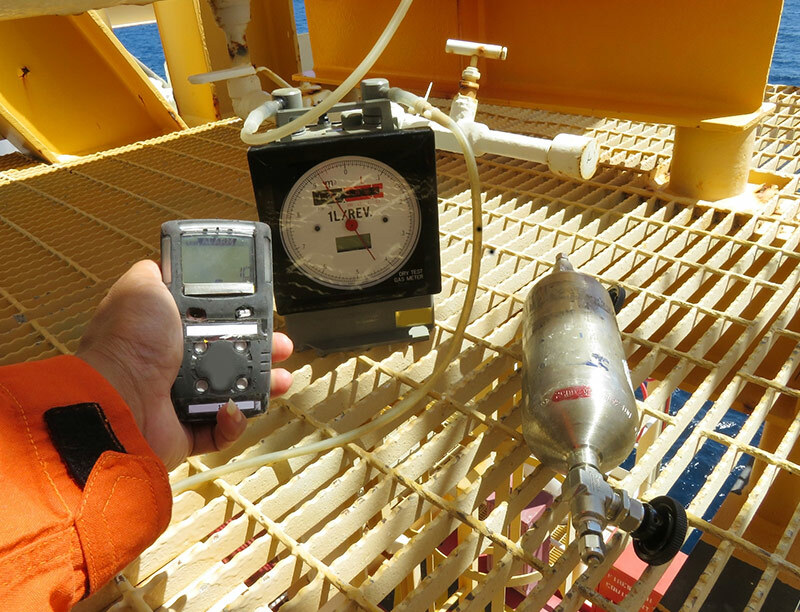

Despite the many benefits, the incorporation of microelectronic sensors in industrial markets is not without its challenges. One primary concern is the reliability of power sources for these detectors, especially in hazardous environments or settings that are difficult to service. Industrial settings often involve extreme temperatures, high vibration levels, exposure to harsh chemicals, and other notable stressors.

Conventional batteries, which are commonly used to power sensors, face significant challenges in maintaining consistent performance under such conditions. As these batteries tend to incorporate liquid-state designs that rely on volatile chemical reactions, they are especially susceptible to temperature variations, impurities, leaks, and corrosion, leading to frequent failures and disruptions in critical monitoring processes. The consequences of a sensor failure in industrial settings can range from decreased efficiency to severe safety hazards.

In the quest for a solution to these challenges, industries are actively seeking safe and reliable power sources that can withstand the demanding conditions of industrial environments. Power source reliability and longevity are critical factors in ensuring uninterrupted sensor operation and, by extension, the smooth functioning of industrial processes.

Sensors in Industrial Markets

Temperature Sensors

Temperature sensors are critical to monitoring the thermal conditions of machinery and processes, ensuring that they operate within optimal ranges.

Pressure Sensors

Pressure sensors help maintain the right pressure levels in manufacturing and energy production, contributing to efficiency and safety.

Motion Sensors

Motion sensors are employed for security and monitoring purposes, detecting any unexpected movements or deviations from predefined patterns.

Water Sensors

Common sensors used to measure water or other liquids include flow sensors and level sensors. These detectors are often employed in chemical processing, water treatment, or manufacturing plants to measure the level of liquids in containers or the movement of liquid within pipes.

Proximity Sensors

Proximity sensors detect an object’s presence (or absence) within a certain range. They are used in various industrial applications, including automation and robotics.

Accelerometers

Accelerometers measure acceleration and vibration in industrial machinery. They are crucial for predictive maintenance, helping identify potential issues before they can lead to equipment failure.

City Labs: Powering the Future of Industrial Markets

The importance of sensors in industrial markets cannot be overstated. They are crucial for data-driven decision-making and automation in diverse sectors. However, their effectiveness hinges on the reliability of the power source, a challenge that conventional batteries often cannot surmount.

Our NanoTritium™ batteries have emerged as an innovative and groundbreaking solution to address industrial market sensor needs, offering long-term reliable performance for sensors and other low-power microelectronic devices. As industrial markets continue to advance, the need for sensors equipped with resilient power solutions becomes increasingly critical. City Labs is dedicated to playing a role in this technological revolution and is always open to partnering with companies interested in upgrading their operational capabilities.

For further information on how NanoTritium™ batteries can revolutionize power solutions for industrial sensors, contact City Labs today.

The Nuclear Battery Company With a Vision

Ready to power your next innovation or learn more about our technology?

Contact Us Today