In an era where technology is pivotal to enhancing the safety and longevity of critical infrastructure, structural integrity sensors have emerged as indispensable tools. These sensors serve as the guardians of our bridges, buildings, and other vital structures, continuously monitoring for signs of wear, fatigue, or other potential failures. To power these microelectronics reliably and sustainably, City Labs offers an innovative solution that transcends the limitations of traditional power sources.

The revolutionized power landscape brought about by City Labs’ NanoTritium™ battery technology is directly relevant to structural integrity sensors and offers opportunities to enhance operational efficiency and application potential. These tritium-powered nuclear batteries harness the energy generated by the radioactive decay of tritium, a hydrogen isotope with a half-life of 12.32 years. The slow decay of tritium provides reliable power for over 20 years, far surpassing traditional electrochemical batteries.

What Are Structural Integrity Sensors?

Structural integrity sensors are specialized devices designed to detect, monitor, and assess the condition of structures, including bridges, buildings, and pipelines. They are critical to ensuring the safety and longevity of these assets by providing real-time data on factors like stress, strain, temperature, and vibrations. By continuously monitoring these parameters, structural integrity sensors provide vital structural health monitoring by helping to identify potential issues, enabling timely maintenance, and preventing catastrophic failures.

Why Are Structural Integrity Sensors Important?

Structural integrity sensors play a pivotal role in enhancing safety and cost-efficiency while promoting sustainability. They are essential for preventing catastrophic outcomes, such as loss of life, property damage, and substantial economic losses, by providing early warnings of potential structural issues.

Moreover, these sensors facilitate cost-effective practices through regular maintenance and timely repairs guided by sensor data, ultimately extending the lifespan of structures and reducing long-term maintenance expenses. Additionally, by enabling proactive maintenance and minimizing the necessity for premature replacements, structural integrity sensors contribute significantly to sustainability by conserving valuable resources.

Without these sensors, it is often impossible to accurately assess structural integrity, leaving no way of knowing if aspects of a structure or its foundation have become critically weakened.

Types of Structural Integrity Sensors

There are several types of structural integrity sensors, each designed to monitor specific aspects of a structure’s health:

Strain Gauges

These sensors measure changes in the deformation or strain of a material, helping identify structural stress and fatigue.

Temperature Sensors

These sensors monitor temperature variations that can reveal potential issues related to material expansion or contraction.

Vibration Sensors

These sensors detect vibrations, which can be used for structural movement monitoring, indicating structural instability or excessive structural movement.

Acoustic Sensors

These sensors listen for unusual sounds that may suggest hidden defects or deterioration within a structure.

Innovative Solutions and Enduring Challenges

Notable Applications of Structural Integrity Sensors

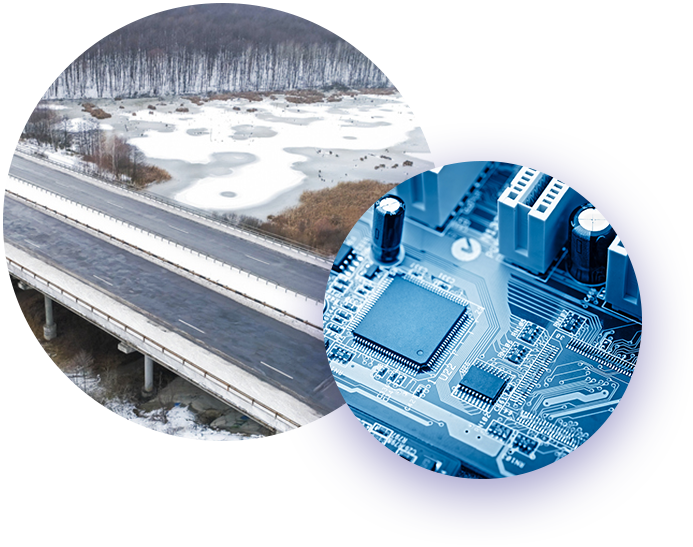

Structural integrity sensors find applications in various critical infrastructure sectors. Sensors placed on bridges monitor load-bearing capacities, detect corrosion, and identify structural defects, ensuring the safety of commuters.

High-rise buildings and historical landmarks also benefit from sensors that detect shifts, settling, and potential structural degradation that can be quickly addressed with the help of these devices. Sensors are also commonly placed along oil, gas, water, and other utility pipelines to monitor for corrosion, leaks, and other issues that could result in environmental disasters.

Notable Industry Challenges

While structural integrity sensors have proven invaluable, there are some persistent challenges in the industry. Power supply reliability is a significant obstacle to be overcome, as most sensors rely on batteries or external power sources, which can fail or require frequent replacement, limiting operational capabilities.

Reliability is also tied to sensor longevity, with extended operational lifespan being highly desirable to limit maintenance needs or battery replacement. Sensors also face unique challenges when deployed in remote or extreme environments, such as arctic regions or deserts, where they may struggle to operate due to temperature variations or other harsh conditions.

City Labs’ NanoTritium™ Batteries: A Sustainable Solution

By relying on this tritium decay rather than the volatile chemical reactions associated with normal batteries, City Labs’ batteries offer a long-term and sustainable power solution, reducing the environmental impact of power sources. In addition, these batteries have undergone rigorous third-party testing to highlight their incredible ability to withstand all sorts of environmental stressors, including extreme temperatures, vibration, radiation, and other harsh conditions, granting them numerous potential applications involving low-power microelectronics, including those that employ structural integrity sensors.

In a world where the integrity of infrastructure is paramount, the role of structural integrity sensors cannot be understated. City Labs’ NanoTritium™ batteries provide a reliable, long-lasting, and sustainable power source, addressing the industry’s most crucial power challenges. By fueling these microelectronics, City Labs contributes to the safety, efficiency, and sustainability of our essential structures, ensuring they stand strong for years to come.

The Nuclear Battery Company With a Vision

Ready to power your next innovation or learn more about our technology?

Contact Us Today