Our planet is ever-changing, and as some of its primary inhabitants, it benefits us to be aware of those changes. That’s why humans are constantly striving to monitor and understand small variations in large-scale environments. To do so, we must measure alterations in temperature, pressure, and sometimes electricity.

This data can help us understand not only the world we live in, but also the things we have created. How much energy does a fridge use? What is the internal temperature of a computer during high-usage periods? We are able to track this information thanks to small microsensors that are powered by tiny batteries.

What Is a Microsensor?

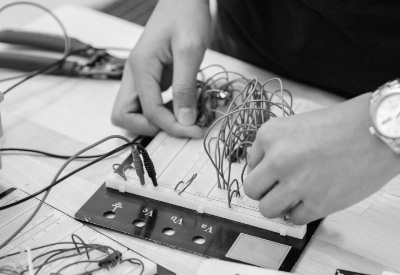

A microsensor is a microelectronic device that monitors analog inputs from the surrounding environment and sends them to a processor as electrical data. They are used by the military, weather service, NASA, electronics companies, and a multitude of other industries to help oversee critical parameters.

The ability to remotely assess how a complex system is functioning based on small bits of electrical data opens a world of possibilities. If a microsensor is well-designed and has an adequate battery, the potential becomes virtually limitless.

How Does a Microsensor Work?

Microsensors monitor their surroundings for the purpose of simplified data collection. Each sensor must have some form of input peripherals to measure external metrics. There must then be a control center that receives the data from these peripherals and records it in a comprehensible manner. Lastly, sensors usually have a communication component allowing them to either wirelessly transfer information or send a ping to a remote location.

With these parts, a sensor can successfully record and convert mechanical data into electrical data that is easily relayed back to a linked system.

Track and Measure Electrical Output

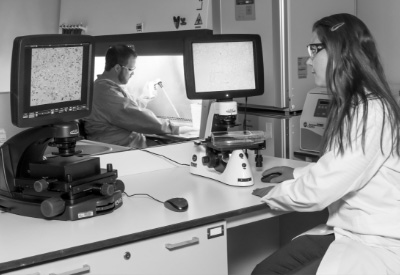

Microsensors can measure a variety of metrics, including changes in electricity, temperature, and pressure. Electrical power sensors have the power to monitor current, voltage, and power levels frequently.

If you are collecting data on a specific machine, you might hook up an electrical sensor to continuously track the energy output at different moments in time. This can provide insight into how the device functions during certain processes or under specific conditions.

Environmental temperature sensors can be useful for observing long-term climate changes, particularly in areas that are difficult to reach. Microsensors can be installed in more remote locations to provide constant data we might otherwise not be able to measure. Pressure sensors are also useful for recognizing seismic and tectonic activity that helps us more accurately depict and predict certain natural phenomena.

Report Threshold Activations

Microsensors are not always expected to be in constant contact with their home base. Sometimes a power sensor is built to operate independently unless it records metrics or measurements above a certain level. This level is called the threshold, and usually indicates some sort of unusual occurrence. When a threshold is activated, the microsensor will send a ping through the linked network to notify the necessary party.

This could be used to measure the temperature of a specific power plant where production becomes dangerous when the environment reaches 130ºF. A thermal power sensor will quietly monitor the heat without sending data back to a remote base. If there is an issue at the plant which leads the system temperature to increase, the sensor might activate at 115ºF to notify those in charge that things are trending in a hazardous direction. This would allow them to take the necessary steps to prevent an accident by addressing the heat spike or temporarily halting production.

Environmental and Power Sensor Batteries

These microelectronic devices can only perform their tasks when they have access to a power supply. Since many of these devices are used to measure metrics in a larger system or a remote area, cords and wires are a less practical option. Internal and external batteries are the main sources of power for microsensors.

Typically, the power supply is built into the sensor, that way it is protected and easily accessible by the device. The battery continuously charges a secondary power storage from which energy is routinely taken when the power sensor activates.

How Long Do Power Sensor Batteries Last?

Calculating the lifespan of current microsensor batteries can be difficult because they have a multitude of functions. For example, many power and temperature sensors use different amounts of energy when they are resting, recording data, and transmitting. This means that the available power might vary over the course of the use.

Additionally, electrochemical batteries can degrade in efficiency after exposure to extreme temperature conditions. This can shorten the estimated battery life even when the environment returns to normal.

Although we cannot give you a uniform length of time that all sensor batteries will survive, we can tell you that the introduction of tritium battery technology will greatly improve the durability, reliability, and lifespan of microsensor batteries.

What Happens When a Power Sensor Battery Gets Low?

Power sensors work to maintain a steady system of information between different nodes. This could be as simple as tracking the temperature in a single area, or as complex as providing comprehensive data to the Internet of Things (IoT).

The IoT represents the network of physical objects that are digitally interconnected by a variety of sensors and softwares. This allows for a smooth transfer of knowledge from one device to the next. Basic kitchen appliances, complex industrial machines, computers, and many more things are linked by the internet.

When power sensors die, they cause breaks or gaps in the IoT, making it more difficult to fill in necessary information. Just like an independent power sensor dying might mean that you won’t receive the data you want.

Maintaining battery power within microsensors is integral to keeping an updated database on vital metrics. If there is another device that relies on the power sensor’s readings, it will not be activated to perform its function.

Applications for Microelectronic Sensors

Microsensors aim to fill in gaps of information that we as humans cannot easily obtain. Whether this is because of environmental conditions or physical location, these versatile devices revitalize efforts to map out patterns in areas that are not convenient.

Power Sensors in Extreme Temperatures

Sometimes the metrics we need are only available in harsh environments. This could imply freezing cold weather conditions, or unbearably hot locations. Both extremes are difficult for humans—and some devices—to handle. Microsensors can be specially designed for particular circumstances, allowing them to perform their task when necessary.

Power Sensors in Remote Locations

Another main function of microsensors is to record metrics or data that would be otherwise difficult to measure. It’s not practical to have a human sitting 200 feet below the ocean’s surface for 12 hours each day. There might be extremely valuable insight to gain from having somebody down there, but it doesn’t matter if we can’t constantly monitor the environment. A sensor can do that job with much less risk—and for much longer.

One location that power sensors have truly been harnessed is space. Beyond the outer reaches of our planet, small devices can measure temperature changes on other planets, electrical impulses sent out by NASA rovers, and other important data. In the years to come, electrical sensors will have a lot of responsibility placed on them to deliver results over long distances and periods of time.

Limitations on Power Sensor Batteries

Assuming a device is built to last, power will be the main limit to its lifespan. The device must have some energy source to carry out its task, and when that source ceases to provide, the device becomes useless. The field of microelectronics craves consistent and reliable batteries that can withstand the test of time.

Batteries for microsensors have struggled in the past to keep up with technological advances—City Labs is working to change that.

City Labs’ NanoTritium™ Batteries for Long-Lasting Power Sensors

City Labs has developed betavoltaic batteries that can output sufficient power for more than 20 years. By using tritium—a relatively benign isotope of hydrogen—as a primary energy source, our radioisotope generators can produce a reliable flow of electricity even under extreme conditions.

Not to mention that the tritium we use is gathered from nuclear waste and stabilizes after use. This means you can help to protect the environment while also harnessing long-lasting, efficient nuclear energy.

The Nuclear Battery Company With a Vision

Ready to power your next innovation or learn more about our technology?

Contact Us Today