City Labs’ NanoTritium™ Batteries Are Third-Party Tested

City Labs is the leading name in tritium nuclear battery technology. We have pioneered novel NanoTritium™ batteries that are taking the microelectronics field by storm. These nuclear batteries differ from traditional batteries in overall cost, total lifespan, functionality, and more.

City Labs’ NanoTritium™ batteries boast a combination of groundbreaking and innovative features that have earned them their reputation:

- Advanced customization options for a variety of technology applications

- Immense downscaling capabilities to fit microelectronic devices

- Extremely long battery life exceeding 20 years of continuous power

- Resistance to both extreme temperatures and harsh environmental stressors, such as radiation, vibration, and altitude

Third-Party Testing Results

Each battery undergoes rigorous testing by City Labs. In addition to in-house battery reliability testing, we also ensure robust battery quality through external testing. For example, third-party testing on City Labs’ P100 Series NanoTritium™ battery was carried out by leading global security and aerospace company Lockheed Martin, who confirmed the extreme temperature variation resistance (-55°C to +150°C) of these batteries.

This type of independent testing provides confidence in the performance and reliability of these novel batteries for future technology applications, as well as important information for battery safety testing procedures.

Lifespan of 20+ Years

One of the main benefits of City Labs’ NanoTritium™ batteries is their incredible lifespan. These batteries are powered by tritium, which has a half-life of 12.32 years. Even after 20 years of continuous use, a NanoTritium™ battery can still output around 33% of its original power capabilities.

Normal batteries seldom have enough chemical fuel to last 20+ years and rely on volatile chemical reactions to create a charge, which are prone to leaks and corrosion over time. These issues are further exacerbated by environmental stressors and temperature variations that tritium-based batteries are resistant to.

Battery Performance Test

A series of battery performance tests have allowed vital parameters to be established for City Labs’ NanoTritium™ batteries, including operational temperature range, external pressure, vibration, and more. In addition, the lengthy lifespan can be accurately showcased by performing simulations to expose battery components to 20+ years’ worth of electron emissions. When faced with these prolonged stressors, NanoTritium™ batteries continue to operate, providing both long-term functionality and reliability.

City Labs remains an active player in battery performance research, sharing key findings with the scientific community as we continue to improve our products and help pave the way for future technological advancements on a global scale.

Extreme Heat and Cold Resistance

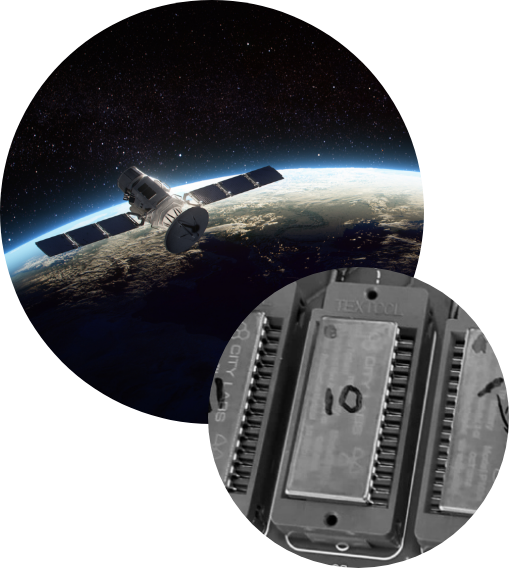

NanoTritium™ batteries can operate at an enormous temperature range between -55º C and 150º C. This vast performance range opens up a much wider field of use applications than traditional batteries, including spacecrafts, satellites, and any other device requiring a reliable power source in the cold.

Radiation Durability

Radiation exposure is also a concern for some battery applications, particularly satellites, which must resist a large amount of ionizing radiation present above the Earth’s atmosphere. In addition to the impressive temperature resistance displayed by NanoTritium™ batteries, they have also been shown to endure much higher radiation levels than standard electrochemical battery cells. Such radiation-tolerant technological components are necessary for most spacecraft devices and even have applications for nuclear power plant power sources.

Battery Testing Standards

The combination of in-house and third-party testing has allowed City Labs to confidently report the exact parameters of our novel NanoTritium™ batteries. Through this exhaustive series of tests, these batteries’ safety, longevity, and many potential applications have been solidified.

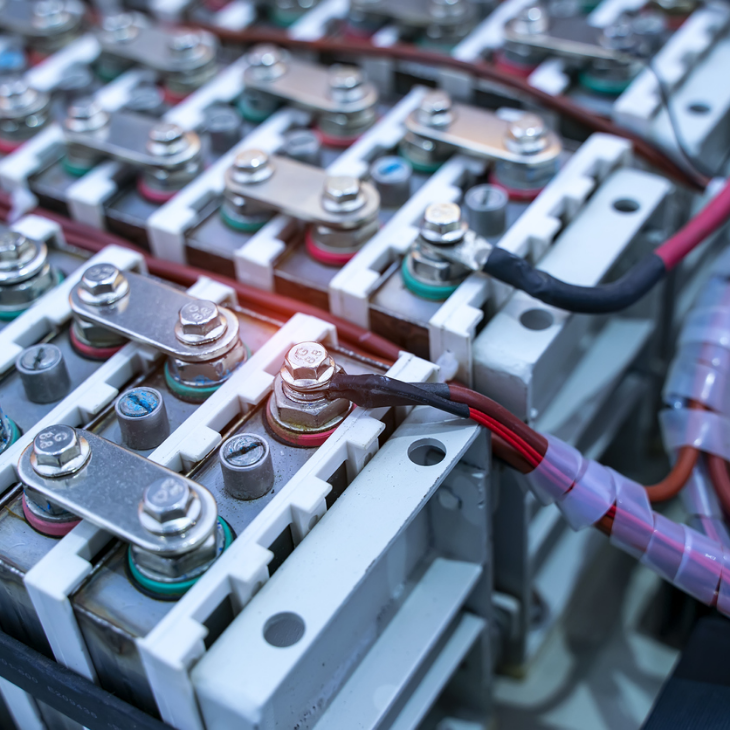

Lithium Ion Battery Testing

It is important to note the difference in battery testing procedures for City Labs’ NanoTritium™ batteries compared to lithium-ion batteries, which largely replaced nickel-cadmium batteries for most portable power supplies in the early 1990s. Lithium-ion batteries, which are much more commonplace in commercial settings, have distinct qualities that necessitate unique testing parameters.

Key properties of lithium-ion batteries include high energy density, a lack of memory and scheduled cycling for extending battery life, a low self-discharge rate, higher cell voltage, fewer cells, high fragility, issues related to capacity deterioration over time, and more. These differences have necessitated novel research in order to even test the operation of nuclear battery components and speak further to the groundbreaking science enabled by City Labs and our partners.

The Importance of Battery Testing

A battery’s primary function is to safely and effectively deliver power to a specified load. As battery-powered devices cannot function without their source of power, it is crucial to ensure that selected batteries have undergone a series of robust testing procedures to confidently determine important specifications, including longevity, durability, and overall performance.

The planned use case for a battery will largely determine what specifications are most important in this testing process. For example, batteries that power satellites must withstand heavy vibrations, extreme heat and cold, solar radiation, and other stressors. More massive batteries that store a large amount of power and can be repeatedly charged are better suited for applications such as electric vehicles, while computer chips and other microelectronics require extremely small batteries.

Although the exact testing procedures vary based on circumstances, rigorous testing still serves the same goal across the board in providing confidence for continued device operation.

What Is Battery Testing?

Battery testing is a series of measurements, stress tests, and diagnostics performed on a battery to specify vital parameters affecting overall function and performance. Examples of such specifics include determining battery charge capacity, resistance and impedance, longevity, discharge rate, heat generation, safety, overall robustness, and more.

Battery Testing Procedure

Standard battery testing procedure includes numerous direct and indirect measurements to analyze normal operating parameters related to power, longevity, durability, etc. Battery safety testing is also important, as it provides crucial information on any short and long-term risks associated with normal battery operations.

The exact analyses that are carried out for testing will vary depending on what kind of battery is being analyzed (e.g., lithium-ion vs. nuclear batteries), as each has unique parameters and potential shortcomings relevant to their desired applications.

Regardless of battery type, the most important part of any testing procedure is to ensure that test conditions are explicitly specified so that any obtained results can be repeated and contrasted with other battery tests to draw meaningful comparisons. Third-party testing is also beneficial, as it provides external validation and increased confidence in product performance.

Check Out City Labs’ NanoTritium™ Battery

Read about our NanoTritium™ technology and see how it works. If you are looking for long-lasting, low-energy betavoltaic power sources to power your microelectronics, don’t hesitate to reach out to us. City Labs is always looking for new commercial partners to work with.

Contact Us Today