October 2025 | Tips & Information

Can Betavoltaic Batteries Really Power Your Next Engineering Project?

An engineering project is only as good as its weakest link. Often, that link is the power source. If your battery fails under heat, vibration, or long-term deployment, your entire design suffers. Engineers are under pressure not only to meet functionality requirements but also to deliver systems that are safe, reliable, and cost-effective.

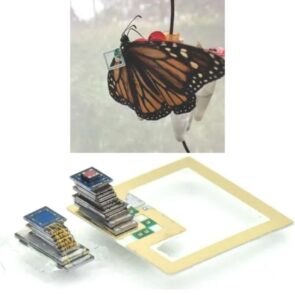

Betavoltaic batteries, once viewed as niche, are now being validated as practical engineering power sources for projects that require long-lasting, maintenance-free energy. This article explores how City Labs’ NanoTritium™ batteries measure up in terms of performance, integration, and application potential.

What Are Betavoltaic Batteries?

Betavoltaic batteries generate electricity by converting the energy of beta particles—natural byproducts of radioactive decay—into current using a semiconductor junction. At the core of this technology is a solid-state device that captures the kinetic energy of tritium, a safe, low-energy isotope of hydrogen, and converts it into usable electricity.

Unlike lithium-ion or alkaline cells, betavoltaics do not rely on chemical cycling. There are no electrolytes to leak, no electrodes to degrade, and no cycling processes that gradually reduce capacity. Instead, the battery’s performance is steady and predictable, making it ideal for ultra-low-power devices. The fully encapsulated, solid-state design ensures safety and reliability across decades of continuous operation.

For engineers, this translates into freedom from recharging cycles and battery swaps. Devices can be deployed once and expected to function reliably for the entirety of their mission profile—whether that’s a sensor buried in arctic ice or a monitoring device orbiting Earth.

This architecture also opens opportunities for engineers designing for extreme conditions where reliability matters more than output. Understanding the underlying science helps teams evaluate where betavoltaics outperform traditional chemistries.

Data Snapshot: Betavoltaic Performance by the Numbers

When evaluating a new power source, engineers need data, not marketing claims. City Labs’ NanoTritium™ batteries provide clear, measurable performance specifications:

- Power output: nanowatts to several microwatts, depending on the model and configuration

- Lifespan: 20+ years of continuous, maintenance-free output

- Temperature tolerance: reliable from –55 °C to +150 °C, with proven stability under repeated thermal cycling

- Form factor: millimeter-to-centimeter scale packages, hermetically sealed and encapsulated

- Safety: Designed to be NRC- and DOT-compliant

These specifications underscore that betavoltaics are not intended for high-drain applications such as motors or processors. Instead, they are uniquely suited for long-duration micro power applications, where continuous, stable output is more important than bursts of energy. Engineers evaluating these specs can model expected performance in mission-critical systems, giving them confidence during the design phase.

Where Betavoltaics Excel

Not every project is a good fit for betavoltaics. But in specific applications where traditional batteries routinely fail, they provide unmatched advantages.

In aerospace missions, components face intense vibration, radiation, and temperature swings. A traditional chemical battery would require regular replacement or might degrade unpredictably, creating unacceptable risk. Betavoltaics, however, provide continuous energy regardless of environmental extremes.

In medical applications, betavoltaics enable implantable devices that do not require repeated surgical replacement. This benefit is not just technical but human, reducing risk and cost for patients while improving quality of life. For device makers, this opens the door to new generations of implants that are smaller, longer lasting, and more patient-friendly.

In industrial settings, pipeline sensors or environmental monitors are often placed in inaccessible or hazardous areas. Dispatching technicians to replace or recharge batteries is expensive and sometimes dangerous. Betavoltaics eliminate this need entirely, saving operational cost and reducing human exposure to risk.

Defense applications also rely on technologies that must remain reliable in remote or adversarial environments. Maintenance-free batteries with decades of predictable performance reduce logistical strain and strengthen mission readiness for long deployments.

Data-Driven Benefits for Engineers

From an engineering perspective, the benefits of betavoltaics are quantifiable. Systems powered by NanoTritium™ batteries avoid costly downtime from battery failures or swaps. Design flexibility improves because engineers no longer need to accommodate large rechargeable packs or plan for periodic access to power sources.

For example, an array of IoT sensors monitoring structural integrity on a bridge could operate continuously for decades without a single battery replacement. A CubeSat or nanosatellite could collect and transmit data long after its peers, outlasting missions powered by traditional cells. Medical devices such as pacemakers or neurostimulators could deliver continuous therapy without repeated surgeries. The impact of such devices includes reduced cost, improved reliability, and greater resilience. Betavoltaics make it possible to design such devices with confidence that power will not be the weak point in your system.

In addition, by eliminating the need for maintenance cycles, engineers can rethink product lifecycles entirely. Devices can be designed smaller, lighter, and more efficient, because extra space for batteries, charging infrastructure, or service access is no longer required.

Integration Considerations for Your Next Engineering Project

Betavoltaics are best suited for ultra-low-power devices, where continuous trickle power is sufficient to maintain functionality. For systems that require occasional bursts of higher energy, betavoltaics can be paired with capacitors or energy-harvesting modules that store energy and release it as needed.

Compatibility is straightforward: these batteries are designed to work with standard low-power electronics, making integration less disruptive than many engineers expect. The fully hermeticdesign ensures safety and stability, while compliance with NRC and DOT regulations provides a clear path through the regulatory landscape.

City Labs’ engineering team also provides direct support, from prototyping to system-level design, ensuring that integration is seamless. We frequently work with engineers who begin testing prototypes with our P-Series cells and then scale up once their use case application is vetted. This pathway lowers risk while giving teams confidence that their systems can scale.

Disposal and end-of-life management are also addressed through existing regulatory pathways, further simplifying adoption for commercial, medical, and defense partners.

How City Labs Supports Engineering Teams

City Labs recognizes that engineers rely on data, documentation, and testing. That’s why we provide detailed technical specifications, reliability data from real-world testing, and prototype access for validation. Our collaborative approach ensures that NanoTritium™ battery solutions can be evaluated and adapted early in the design cycle.

Beyond the hardware, we work alongside engineering teams to answer questions about regulatory compliance, scaling, and long-term reliability. This partnership model reduces risk for customers and accelerates adoption of betavoltaic technology across industries.

For a closer look at how our batteries handle extreme conditions, review the specs available on our products page.

The Takeaway

Betavoltaic batteries are not a futuristic gamble. They are a proven, regulatory-compliant power solution designed for engineering projects where reliability and longevity are non-negotiable. While they will not replace every type of battery, they excel in compact, mission-critical devices requiring continuous output in demanding environments.

Looking ahead, betavoltaics represent a critical piece of the energy puzzle as engineers push the boundaries of IoT, aerospace exploration, and medical technology. As systems shrink and mission durations extend, the need for power sources that can operate reliably for decades will only grow. So—can they really power your next project? The data, and the applications already in the field, say yes.

If you’re ready to evaluate betavoltaics for your application, contact City Labs today for technical data sheets, prototypes, and engineering support.